Insertking High-Performance Thermal Insulation Blocks - Fire Retardant, PLC Automated Injection Molding

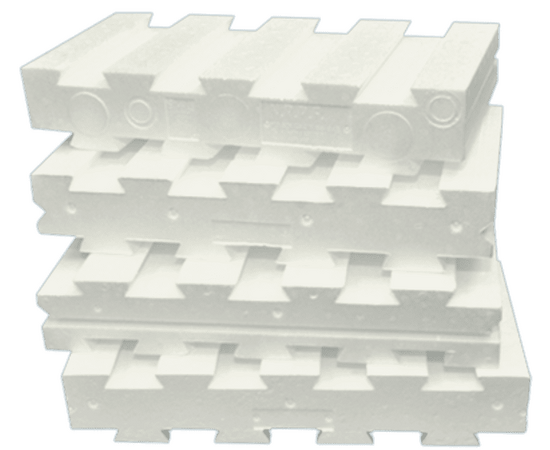

Our INSERTKING Thermal Insulation Blocks are made using fully PLC automated injection molding machines, ensuring that they are of the highest quality and performance. These fire retardant blocks are the perfect insulating medium for a range of construction projects, including single and double wall systems, pre-cast walls, and insulated metal panels. They are also suitable for use in foundation walls, slab-on-grade construction, and exterior insulation and finishing systems (EIFS).

Mandatory for external walls according to Dubai Municipality standards, INSERTKING . In addition to their safety and durability, these blocks are designed to be energy efficient, helping to reduce heating and cooling costs for buildings. Whether you are a builder, contractor, or homeowner, our INSERTKING Thermal Insulation Blocks are an excellent choice for all your insulation needs.

INSERTKING-THERMAL INSULATION BLOCKS.

| No. | Product Description | Brand Name | Dimension | Type |

| 1 | Rigid Cellular Expanded Polystyrene Thermal Block Insert Fire Retardant Grade ** and CFC Free *** | INSERTKING 25 | Size 400 mm X 200 mm 412 mm x 200 mm Thickness 60 mm and 75 mm 110 mm and 160 mm | ASTM Type II Density: 25 kg/m3 (min)* (as per Table 1) |

Note 1: * Minimum density required by Dubai Municipality for block insert

Note 2: ** Minimum acceptable oxygen index as per ASTM C578 is 24 %

Note 3: *** In compliance with clause 701.01 (1) of the Green Building Regulations and Specifications

Note 3: This document forms part of the Certificate of Product Conformity bearing the same certificate number.

Note 4: The above product shall bear the DCL Conformity Mark (applied on each product or on the packaging).

TABLE 1. PHYSICAL PROPERTY REQUIREMENTS OF RIGID CELLULAR EXPANDED POLYSTYRENE THERMAL INSULATION

| SN | PROPERTIES | TYPE XI | TYPE I | TYPE VIII | TYPE II | TYPE IX | TYPE XIV | TYPE XV |

1 | COMPRESSIVE RESISTANCE © yield or 10% deformation, which occurs first, min kPa | 35 | 69 | 90 | 104 | 173 | 276 | 414 |

2 | THERMAL RESISTANCE of 25.4 mm thickness, @ mean temp. of 24±1°C min, K-m2/W | 0.55 | 0.63 | 0.67 | 0.70 | 0.74 | 0J4 | 0.76 |

3 | THERMAL CONDUCTIVITY, max, Win K @ 35°C and 60% RH | 0.0482 | 0.0419 | 0.0394 | 0.0377 | 0.0356 | 0.0356 | 0.0347 |

4 | FLEXURAL STRENGTH, min, kPa | 70 | 173 | 208 | 240 | 345 | 414 | 517 |

5 | WATER VAPOR PERMEANCE of 25.4 mm thickness, max, perm | 5.0 | 5.0 | 3.5 | 3.5 | 2.5 | 2.5 | 2.5 |

6 | WATER ABSORPTION by total immersion, max volume % | 4.0 | 4.0 | 3.0 | 3.0 | 2.0 | 2.0 | 2.0 |

7 | DIMENSIONAL STABILITY (change in dimension), max, % | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

8 | OXYGEN INDEX, min, volume % | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

9 | DENSITY, min, kg/m3 | 12 | 15 | 18 | 22 | 29 | 38 | 46 |

- NOTE: THE ABOVE SPECIFICATION VALUES ARE EXTRACTED FROM TABLE I OF ASTM C578

- APPLICATIONS

- Thermal Insulation sheets, Single wall system, Double wall system, Pre-cast wall system, Profiled insulated metal panels, Vibration isolation, Foundation walls, Insulating sheathing over existing construction, Insulating sheathing over new construction, Slab-On-Grade Construction, Exterior insulation & Finishing system (EIFS)

No reviews found